Securing Manufacturing Data: Cybersecurity Strategies for Industry 4.0 Protection

Explore comprehensive cybersecurity strategies for securing manufacturing data in Industry 4.0 environments, addressing OT/IT convergence, ransomware threats, supply chain security, and emerging cyber risks facing modern manufacturing organizations.

Introduction

The Manufacturing Cybersecurity Crisis

Manufacturing organizations face a perfect storm of cybersecurity challenges as they embrace Industry 4.0 technologies while maintaining legacy systems that create significant vulnerabilities. The sector has become the most targeted industry due to the critical nature of manufacturing operations and the valuable intellectual property they possess, with attackers increasingly sophisticated in their understanding of operational technology environments. Cybersecurity now ranks among the top three risks to manufacturing, trailing only inflation and economic growth, as more than half of manufacturers consider securing their operational technology assets a primary factor in technology investment decisions.

Manufacturing Under Siege

Between 2024-2025 Q1, there were 29 active threat actors targeting manufacturing, with 79% being cybercriminals and 45% ransomware gangs. Ransomware attacks on industrial control systems doubled in 2022, while phishing represents 39% of initial infection vectors in the manufacturing industry.

- Ransomware Operations: Sophisticated groups like RansomHub, LockBit 3.0, and Akira specifically targeting manufacturing systems with advanced encryption and double extortion tactics

- Intellectual Property Theft: Nation-state actors and cybercriminals targeting proprietary designs, trade secrets, and manufacturing processes for economic advantage

- Supply Chain Attacks: Threat actors exploiting interconnected supplier networks to gain access to multiple organizations through single compromise points

- Operational Technology Targeting: Increasing attacks on industrial control systems, SCADA networks, and production line equipment

- Cloud Infrastructure Exploitation: Attacks leveraging cloud misconfigurations as manufacturers adopt cloud technologies for scalability and efficiency

IT/OT Convergence Security Challenges

The convergence of Information Technology and Operational Technology systems creates unprecedented security challenges as traditionally isolated industrial networks become connected to corporate IT infrastructure and the internet. Legacy OT systems were designed for reliability and safety rather than security, often lacking basic security controls like encryption, authentication, and monitoring capabilities. This convergence enables attackers to move laterally from IT networks into critical production systems, potentially causing physical damage, safety incidents, and operational disruption that extends far beyond traditional cybersecurity impacts.

| System Type | Primary Vulnerabilities | Attack Consequences | Protection Strategies |

|---|---|---|---|

| Industrial Control Systems | Unpatched vulnerabilities, weak authentication, clear-text protocols | Production shutdown, safety incidents, equipment damage | Network segmentation, monitoring, access controls |

| SCADA Networks | Remote access vulnerabilities, legacy systems, poor encryption | Process manipulation, data corruption, regulatory violations | Secure remote access, encryption, continuous monitoring |

| Manufacturing Execution Systems | Integration vulnerabilities, privilege escalation, data exposure | Production disruption, intellectual property theft, quality issues | Application security, identity management, data protection |

| Human-Machine Interfaces | Default credentials, software vulnerabilities, unauthorized access | Operator disruption, process interference, safety risks | Credential management, patch management, user training |

Network Segmentation and Zero Trust Implementation

Network segmentation represents the foundational security control for manufacturing environments, isolating critical production systems from corporate networks and limiting lateral movement opportunities for attackers who breach perimeter defenses. Effective segmentation requires implementing security zones based on criticality, function, and trust levels while maintaining necessary connectivity for business operations. Zero Trust architectures extend this concept by eliminating implicit trust assumptions and requiring continuous verification of every user, device, and transaction attempting to access manufacturing systems.

- Micro-Segmentation: Granular network controls isolating individual systems or functions to contain potential breaches

- Security Zones: Logical groupings of systems with similar security requirements and controlled inter-zone communication

- Continuous Verification: Real-time validation of user and device identity, posture, and behavior before granting system access

- Least Privilege Access: Minimal access rights based on specific job functions and time-limited permissions

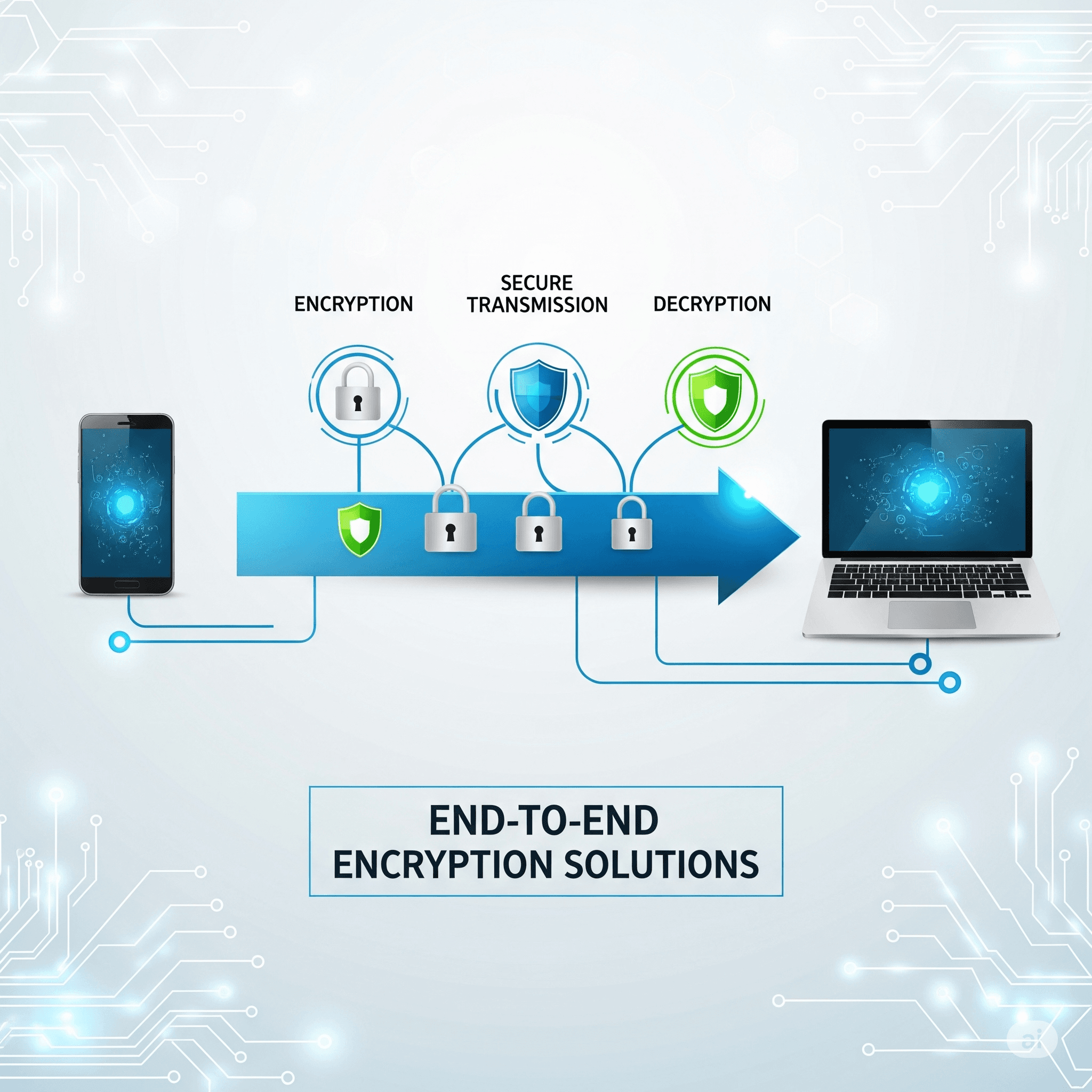

- Encrypted Communications: End-to-end encryption for all data transmission between manufacturing systems and networks

Supply Chain Cybersecurity and Third-Party Risk Management

Manufacturing supply chains represent critical cybersecurity vulnerabilities as organizations become increasingly interconnected through digital platforms, shared systems, and integrated business processes. Supply chain attacks enable threat actors to access multiple organizations through single compromise points, leveraging trusted relationships and interconnected systems to move laterally across supplier networks. Effective supply chain cybersecurity requires comprehensive risk assessment, continuous monitoring, and contractual security requirements that extend protection across the entire manufacturing ecosystem.

Supply Chain Security Imperative

Manufacturing organizations must establish baseline security maturity requirements for critical software and service providers while continuously monitoring for breaches related to third-party tools used within their operations, as supply chain compromises can have cascading effects across entire production networks.

Ransomware Defense and Business Continuity

Ransomware represents the most significant immediate threat to manufacturing operations, with sophisticated groups developing specialized capabilities for targeting industrial environments and maximizing operational disruption. Modern ransomware operations employ double and triple extortion tactics, threatening both data encryption and public disclosure of sensitive information while targeting backup systems and recovery capabilities to maximize leverage over victims. Effective ransomware defense requires comprehensive strategies that prevent initial compromise, limit damage if prevention fails, and ensure rapid recovery to minimize production downtime.

Identity and Access Management for Manufacturing

Manufacturing environments require specialized identity and access management approaches that address unique operational requirements including 24/7 production schedules, shared workstations, emergency access needs, and integration with industrial systems that may not support modern authentication methods. Effective IAM implementation must balance security requirements with operational continuity, ensuring that legitimate users can access necessary systems while preventing unauthorized access that could disrupt production or compromise safety.

IAM Best Practices

Manufacturing IAM strategies should enforce multi-factor authentication whenever possible, implement role-based access controls aligned with job functions, and maintain detailed access logs to detect suspicious activity while supporting operational requirements for shared resources and emergency access.

Emerging Technology Security Risks

The adoption of emerging technologies including digital twins, artificial intelligence, 5G networks, and cloud-native manufacturing platforms introduces novel security risks that require proactive assessment and specialized protection strategies. Digital twins create risks to data models and potential for sabotage through manipulation of virtual representations that control physical processes. AI and machine learning systems face risks from algorithm manipulation and data poisoning attacks that could compromise manufacturing quality and safety systems.

- Digital Twin Vulnerabilities: Risks to data models, simulation accuracy, and potential for virtual-to-physical attack propagation

- AI/ML Security: Algorithm manipulation, training data poisoning, and adversarial attacks on manufacturing AI systems

- 5G Network Risks: New attack vectors for initial access, command and control, and encrypted traffic that evades detection

- Cloud Misconfigurations: Security gaps in cloud deployments that expose manufacturing data and systems to unauthorized access

- Edge Computing Threats: Distributed attack surfaces and limited security visibility in edge manufacturing environments

Incident Response and Crisis Management

Cybersecurity incidents in manufacturing environments require specialized response procedures that consider both digital and physical safety implications while minimizing production disruption and ensuring worker protection. Manufacturing incident response must coordinate between IT security teams, operational technology specialists, safety personnel, and business leadership to address complex scenarios where cyber attacks can cause physical damage or safety hazards. The average time to identify and contain breaches in industrial organizations exceeds 270 days, making rapid detection and response critical capabilities for manufacturing cybersecurity.

| Response Phase | Key Activities | Manufacturing Considerations | Success Metrics |

|---|---|---|---|

| Detection | Threat identification, alert validation, impact assessment | Safety system monitoring, production impact evaluation | Mean time to detection, alert accuracy |

| Containment | Isolate affected systems, prevent spread, preserve operations | Safe shutdown procedures, alternative production paths | Containment speed, production continuity |

| Eradication | Remove threats, patch vulnerabilities, restore integrity | OT system validation, safety verification | Threat elimination, system integrity |

| Recovery | System restoration, service resumption, monitoring | Production restart, quality assurance, performance validation | Recovery time, operational performance |

Security Awareness and Human Factors

Human factors represent significant vulnerabilities in manufacturing cybersecurity, with phishing attacks serving as the top initial infection vector in 39% of manufacturing incidents. Manufacturing employees often have diverse technical backgrounds and may not receive regular cybersecurity training, making them susceptible to social engineering attacks that target industrial environments. Effective security awareness programs must address both general cybersecurity principles and manufacturing-specific threats while accommodating shift work, multilingual workforces, and varying technical skill levels.

Regulatory Compliance and Standards

Manufacturing cybersecurity must address diverse regulatory requirements spanning industry-specific standards, national cybersecurity frameworks, and international compliance obligations that vary by sector, geography, and customer requirements. Key frameworks include NIST Cybersecurity Framework, ISO 27001, IEC 62443 for industrial automation security, and sector-specific requirements for automotive, aerospace, pharmaceutical, and other regulated industries. Compliance strategies must balance security requirements with operational needs while maintaining auditability and demonstrating continuous improvement.

Compliance Complexity

Manufacturing organizations must navigate complex regulatory landscapes that include cybersecurity frameworks, industry standards, and sector-specific requirements while maintaining operational efficiency and demonstrating continuous security improvement.

Future Security Challenges and Preparedness

The future of manufacturing cybersecurity will be shaped by continuing digital transformation, evolving threat landscapes, and emerging technologies that create new attack surfaces and security challenges. Organizations must prepare for quantum computing threats that will require new cryptographic approaches, increased use of artificial intelligence by both attackers and defenders, and greater integration of cyber-physical systems that blur the boundaries between digital and physical security. Proactive security strategies must anticipate these changes while building adaptive capabilities that can evolve with emerging threats and technologies.

- Quantum-Resistant Cryptography: Preparing for quantum computing threats through post-quantum encryption implementations

- AI-Powered Defense: Leveraging artificial intelligence for threat detection while defending against AI-enhanced attacks

- Cyber-Physical Integration: Addressing security challenges as digital and physical systems become increasingly interconnected

- Autonomous Security: Developing self-healing security systems that can respond to threats without human intervention

- Predictive Risk Management: Using advanced analytics to anticipate and prevent security incidents before they occur

Conclusion

Securing manufacturing data in the era of Industry 4.0 represents one of the most complex cybersecurity challenges facing modern organizations, requiring comprehensive strategies that protect both digital assets and physical operations while enabling the connectivity and automation essential for competitive manufacturing. With manufacturing identified as the most targeted industry and facing sophisticated threats from ransomware gangs, nation-state actors, and cybercriminals seeking valuable intellectual property, organizations must implement defense-in-depth approaches that address the unique convergence of IT and OT systems. Success requires balancing security imperatives with operational continuity, ensuring that protection measures enhance rather than hinder production efficiency while safeguarding the sensitive data and processes that drive manufacturing excellence. The manufacturers who will thrive in this challenging environment are those that embed cybersecurity into their digital transformation strategies, invest in both technology solutions and workforce capabilities, and build adaptive security programs that can evolve with emerging threats and technologies while maintaining the trust and resilience essential for long-term business success.

Reading Progress

0% completed

Article Insights

Share Article

Quick Actions

Stay Updated

Join 12k+ readers worldwide

Get the latest insights, tutorials, and industry news delivered straight to your inbox. No spam, just quality content.

Unsubscribe at any time. No spam, ever. 🚀