Optimizing Operations Through Expert Consulting

Discover how expert consulting services transform business operations through strategic analysis, process optimization, and implementation of best practices that drive efficiency, reduce costs, and align operations with business objectives for sustainable growth.

Introduction

Understanding Operations Consulting Value

Operations consulting provides expert guidance to businesses seeking to optimize their operations by identifying inefficiencies, enhancing processes, and integrating new technologies to achieve better performance and sustained growth. Unlike traditional management consulting that focuses on high-level strategic issues, operations consultants concentrate on day-to-day operational aspects, providing objective evaluations that help identify inefficiencies internal teams might overlook. The specialized approach enables organizations to refine workflows, align operations with strategic goals, and build lasting capabilities that foster sustainable growth and stronger performance while maximizing competitive advantage.

Strategic Impact

Operations consulting focuses on proactively identifying opportunities to enhance business operations rather than just fixing problems, enabling companies to refine processes, optimize resources, and improve their bottom line.

Recognizing the Need for Expert Guidance

As businesses evolve and face growth challenges, they often encounter operational inefficiencies that slow progress and drain resources, making the decision to engage external specialists a strategic move rather than a sign of internal shortcomings. Leaders may sense bottlenecks within supply chains, sales pipelines, and support functions but lack the specialized knowledge or objective perspective needed to address these challenges effectively. Expert consultants bring fresh perspectives and systematic approaches to identifying weak links in processes, enabling companies to immediately draw on wealth of expertise rather than grappling with hidden bottlenecks for years.

- Objective Analysis: External consultants provide unbiased assessments of operational performance without internal politics or preconceptions

- Specialized Knowledge: Access to industry best practices, benchmarking data, and proven methodologies from across multiple sectors

- Fresh Perspective: Outside viewpoint that can identify inefficiencies and opportunities that internal teams may have overlooked

- Rapid Implementation: Immediate access to expertise without the time and cost of developing capabilities internally

- Risk Mitigation: Proven approaches that reduce the risk of failed improvement initiatives and costly mistakes

Process Improvement and Optimization

Process improvement represents the heart of operations consulting, where consultants bring fresh perspectives to identify outdated, inefficient, or redundant processes that impact organizational performance. Operations consultants map current processes, analyze data, and recommend changes that streamline production, reduce downtime, increase efficiency, and enhance the quality of products or services. For example, manufacturing companies often discover production line bottlenecks that slow output, leading to process optimization recommendations that boost productivity, reduce operational costs, and improve overall efficiency.

| Process Area | Common Issues | Consulting Solutions | Expected Outcomes |

|---|---|---|---|

| Manufacturing Operations | Production bottlenecks, equipment downtime, quality inconsistencies | Process mapping, workflow optimization, predictive maintenance | 20-40% increase in throughput, reduced waste, improved quality |

| Supply Chain Management | Inventory inefficiencies, supplier issues, logistics delays | End-to-end analysis, supplier optimization, logistics redesign | 15-25% cost reduction, improved delivery times, better visibility |

| Customer Service Operations | Long response times, inconsistent service, high costs | Process standardization, technology integration, training programs | Improved customer satisfaction, reduced operational costs |

| Financial Operations | Manual processes, errors, compliance issues | Automation implementation, control improvements, system integration | Faster processing, reduced errors, better compliance |

Strategic Alignment and Goal Integration

Effective operations consulting ensures that operational processes align with strategic business objectives by analyzing how products move from concept to customer, how client relationships are nurtured, and how business functions support overarching growth targets. Consultants bring disciplined approaches to closing gaps between strategic aims and daily operational execution, ensuring that every department and workflow supports the organization's mission and avoids wasted efforts on activities that don't advance business objectives. This systematic alignment enables companies to focus improvements on changes that directly support long-term goals rather than random enhancements that may not contribute to strategic success.

Strategic Alignment Benefits

Organizations that achieve strong alignment between operations and strategy through expert consulting typically see 25-35% improvements in goal achievement and significantly better resource utilization.

Supply Chain Management Excellence

Supply chain management represents a critical area where operations consulting delivers significant impact by improving logistics, reducing costs, and enhancing delivery times through comprehensive end-to-end analysis. Retail companies struggling with high inventory costs due to overstocking or customer satisfaction issues from delayed shipments can benefit from consultant analysis that optimizes inventory management, streamlines logistics, and improves supplier relationships. Operations consultants analyze supply chains from suppliers to customers, identifying inefficiencies and implementing strategies that result in more efficient operations supporting business goals and enhanced customer satisfaction.

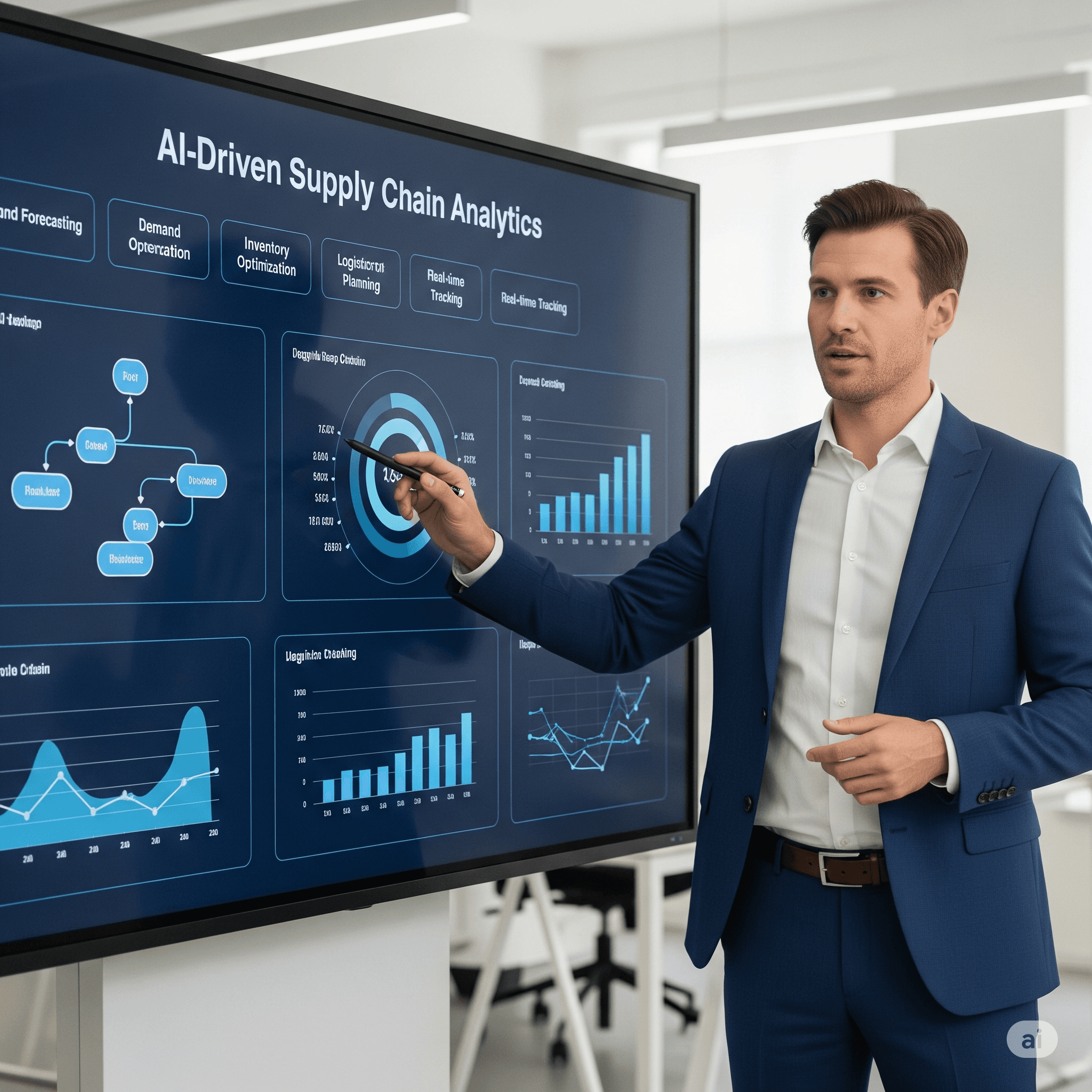

Technology Integration and Digital Transformation

Operations consulting increasingly focuses on technology integration and digital transformation initiatives that enhance process efficiency, data visibility, and decision-making capabilities. Consultants help organizations identify appropriate technologies, plan integration strategies, and manage implementation to ensure technology investments deliver expected returns and operational improvements. By integrating technology with process optimization techniques, consultants propose tailored solutions that enhance operations while addressing specific business challenges and growth objectives.

- Process Automation: Implementing technologies that automate routine tasks and reduce manual intervention

- Data Analytics Integration: Deploying analytics tools that provide insights for better decision-making and performance monitoring

- System Integration: Connecting disparate systems to improve information flow and operational coordination

- Digital Workflow Optimization: Redesigning processes to leverage digital capabilities and improve efficiency

- Performance Monitoring Systems: Implementing tools that provide real-time visibility into operational performance

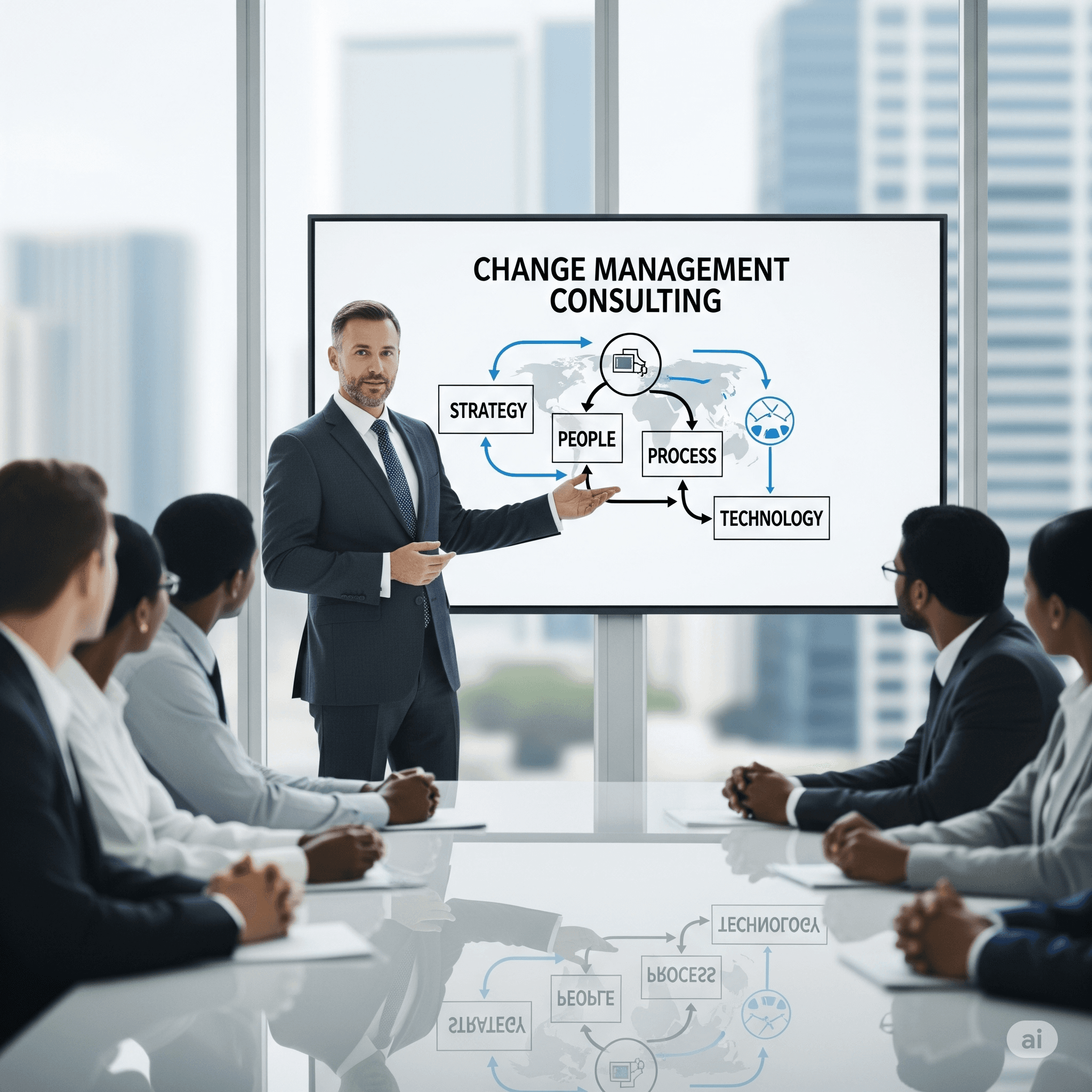

Change Management and Implementation Support

Successful operations consulting requires effective change management to ensure recommendations are implemented successfully and adopted by the organization. Consultants work closely with stakeholders at all organizational levels to secure buy-in and support for operational changes, involving affected employees in the improvement process to foster ownership and cooperation. Effective communication and collaboration are essential for overcoming resistance to change and ensuring that everyone understands the benefits of proposed improvements while building capabilities that sustain performance gains.

Data-Driven Decision Making and Analytics

Operations consulting emphasizes data-driven approaches that use process mapping, performance metrics analysis, and evidence-based recommendations to support improvement initiatives. Process mapping provides visual representations of how tasks are completed, highlighting inefficiencies, redundancies, and bottlenecks that can be addressed through systematic improvements. Data analysis plays a critical role by examining metrics such as cycle times, error rates, and resource utilization to pinpoint specific improvement areas and quantify potential benefits of proposed changes.

Data-Driven Results

Organizations using data-driven operations consulting approaches typically achieve 2-3x better results compared to intuition-based improvement efforts, with more sustainable and measurable outcomes.

Cost Optimization and Efficiency Enhancement

Cost optimization represents a primary benefit of operations consulting, with experienced consultants identifying opportunities to streamline processes, reduce expenses, and maximize efficiency through systematic analysis and improvement. Consultants utilize comprehensive methodologies to examine business operations, supply chains, and financial processes to identify inefficiencies, redundancies, and potential cost savings that may not be apparent to internal teams. The optimization process goes beyond simple cost-cutting to create sustainable strategies that reduce expenses while improving efficiency through streamlined processes, eliminated bottlenecks, and implementation of best practices.

| Cost Optimization Area | Typical Savings Range | Implementation Approach | Sustainability Factors |

|---|---|---|---|

| Process Efficiency | 15-30% operational cost reduction | Workflow analysis, automation, standardization | Training programs, performance monitoring, continuous improvement |

| Resource Utilization | 20-40% improvement in asset utilization | Capacity analysis, scheduling optimization, equipment right-sizing | Regular utilization reviews, performance dashboards, adjustment protocols |

| Supply Chain Costs | 10-25% reduction in procurement and logistics costs | Supplier optimization, inventory management, logistics redesign | Supplier relationship management, contract optimization, performance metrics |

| Quality Improvements | 5-15% cost savings through error reduction | Quality systems implementation, process controls, training | Quality monitoring systems, corrective action processes, culture development |

Industry-Specific Expertise and Applications

Operations consulting delivers industry-specific expertise that addresses unique operational challenges and regulatory requirements across different sectors. For example, urban transit companies benefit from route planning optimization and service reliability improvements to combat rising costs and declining ridership, while boutique hotel chains can improve operational excellence and customer satisfaction despite facing increased complaints and occupancy challenges. Healthcare organizations like nursing care facilities achieve care quality improvements and reduced complaints through operational excellence strategies, while IT services providers reduce project lead times through targeted operational improvements.

Performance Measurement and Continuous Improvement

Effective operations consulting establishes comprehensive performance measurement systems that track improvement progress and identify new optimization opportunities. Consultants help organizations implement key performance indicators, monitoring systems, and feedback mechanisms that enable continuous assessment of operational effectiveness and identification of areas requiring additional attention. The focus on continuous improvement ensures that operational gains are sustained over time while building organizational capabilities to identify and address future challenges independently.

Regulatory Compliance and Risk Management

Operations consultants provide valuable guidance on navigating complex regulatory requirements, market standards, and compliance challenges that can create operational friction if not properly managed. Their familiarity with regulatory frameworks and industry requirements helps organizations adjust operations proactively rather than reacting to compliance issues after they arise. By fine-tuning operational mechanisms, ensuring supply chain reliability, and evaluating risk mitigation approaches, consultants help preserve operational momentum while maintaining compliance and reducing exposure to regulatory penalties.

Compliance Considerations

Organizations that proactively address regulatory and compliance requirements through expert consulting typically avoid 60-80% of potential compliance violations and associated penalties while maintaining operational efficiency.

Stakeholder Engagement and Communication

Successful operations consulting requires comprehensive stakeholder engagement that involves employees, managers, and executives in improvement initiatives to ensure buy-in and support for operational changes. Consultants must work closely with affected personnel to understand current processes, identify improvement opportunities, and address concerns about proposed changes. Effective communication and collaboration throughout the consulting engagement foster ownership and cooperation, increasing the likelihood of successful implementation and sustained improvement.

Implementation Timeline and Project Management

Operations consulting projects require structured project management approaches that balance thorough analysis with timely implementation to achieve expected results within reasonable timeframes. Consultants typically follow phased implementation approaches that begin with assessment and analysis, progress through solution design and pilot testing, and conclude with full-scale implementation and knowledge transfer. Clear project timelines, milestone tracking, and regular communication ensure that consulting engagements remain on schedule while delivering expected outcomes and building internal capabilities.

- Assessment Phase: Current state analysis, performance baseline establishment, and opportunity identification (2-4 weeks)

- Design Phase: Solution development, process redesign, and implementation planning (3-6 weeks)

- Pilot Phase: Small-scale testing, refinement, and validation of proposed improvements (2-4 weeks)

- Implementation Phase: Full-scale rollout, training delivery, and performance monitoring (4-12 weeks)

- Sustainment Phase: Knowledge transfer, documentation, and ongoing support establishment (2-4 weeks)

Return on Investment and Value Measurement

Operations consulting delivers measurable return on investment through improved efficiency, cost reduction, and enhanced performance that can be quantified and tracked over time. Organizations typically achieve 3:1 to 5:1 return on consulting investment through operational improvements, cost savings, and revenue enhancements resulting from optimized processes and strategic alignment. Value measurement includes both quantitative metrics such as cost reductions and efficiency gains, and qualitative benefits such as improved customer satisfaction, employee engagement, and organizational capabilities.

Selecting the Right Operations Consultant

Choosing the right operations consultant requires careful evaluation of expertise, experience, methodology, and cultural fit to ensure successful engagement outcomes. Organizations should define clear goals, research potential consultants thoroughly, and establish strong working relationships that support effective collaboration and knowledge transfer. Key selection criteria include industry experience, proven methodologies, cultural alignment, communication skills, and demonstrated results in similar operational challenges.

| Selection Criteria | Evaluation Methods | Key Considerations | Success Indicators |

|---|---|---|---|

| Industry Expertise | Case studies, client references, sector knowledge assessment | Relevant experience, understanding of industry challenges | Proven results in similar organizations and operational contexts |

| Methodology Approach | Framework evaluation, process documentation, tool assessment | Structured approach, data-driven methods, proven techniques | Clear methodology, measurable outcomes, systematic implementation |

| Cultural Fit | Team interactions, communication style, values alignment | Collaborative approach, organizational compatibility | Positive stakeholder engagement, effective communication, trust building |

| Implementation Support | Project management capabilities, training programs, knowledge transfer | Change management skills, implementation experience | Successful adoption, sustained improvements, capability building |

Future Trends in Operations Consulting

The future of operations consulting will be shaped by increasing integration of digital technologies, data analytics, and artificial intelligence that enable more sophisticated analysis and automated optimization. Emerging trends include predictive analytics for proactive operational management, artificial intelligence for process optimization, digital twin technology for simulation and testing, and advanced automation for routine operational tasks. Consultants will increasingly focus on helping organizations build adaptive capabilities that can respond dynamically to changing market conditions and technological advances.

Building Internal Capabilities

Effective operations consulting emphasizes building internal capabilities that enable organizations to sustain improvements and continue optimizing operations independently after the consulting engagement concludes. Knowledge transfer activities include training programs, documentation development, and mentoring that help internal teams develop skills and understanding necessary to maintain and enhance operational performance. This capability-building approach ensures that consulting investments deliver long-term value rather than temporary improvements that fade after consultant departure.

Sustainable Impact

Organizations that focus on building internal capabilities through operations consulting achieve 40-60% better long-term sustainability of improvements compared to those that rely solely on external implementation.

Conclusion

Operations consulting provides organizations with essential expertise and objective perspectives needed to optimize performance, reduce costs, and build sustainable competitive advantages through systematic operational improvements. The value of expert consulting extends far beyond immediate problem-solving to encompass strategic alignment, capability building, and culture transformation that enables long-term operational excellence and business success. Organizations that engage qualified operations consultants typically achieve significant improvements in efficiency, cost reduction, customer satisfaction, and strategic alignment while building internal capabilities that sustain performance gains over time. As business environments become increasingly complex and competitive, operations consulting will continue to play a critical role in helping organizations adapt, optimize, and thrive through expert guidance, proven methodologies, and systematic improvement approaches that deliver measurable results and lasting value. Success in operations consulting requires careful selection of qualified consultants, clear goal definition, strong stakeholder engagement, and commitment to implementing recommended improvements while building internal capabilities that ensure sustainable operational excellence and continued growth.

Reading Progress

0% completed

Article Insights

Share Article

Quick Actions

Stay Updated

Join 12k+ readers worldwide

Get the latest insights, tutorials, and industry news delivered straight to your inbox. No spam, just quality content.

Unsubscribe at any time. No spam, ever. 🚀