Revolutionizing Supply Chains with Cognitive Technologies

Discover how cognitive technologies are transforming supply chain operations through AI-powered analytics, predictive intelligence, and autonomous decision-making that enable unprecedented efficiency, resilience, and sustainability across global logistics networks.

Introduction

Understanding Cognitive Supply Chain Architecture

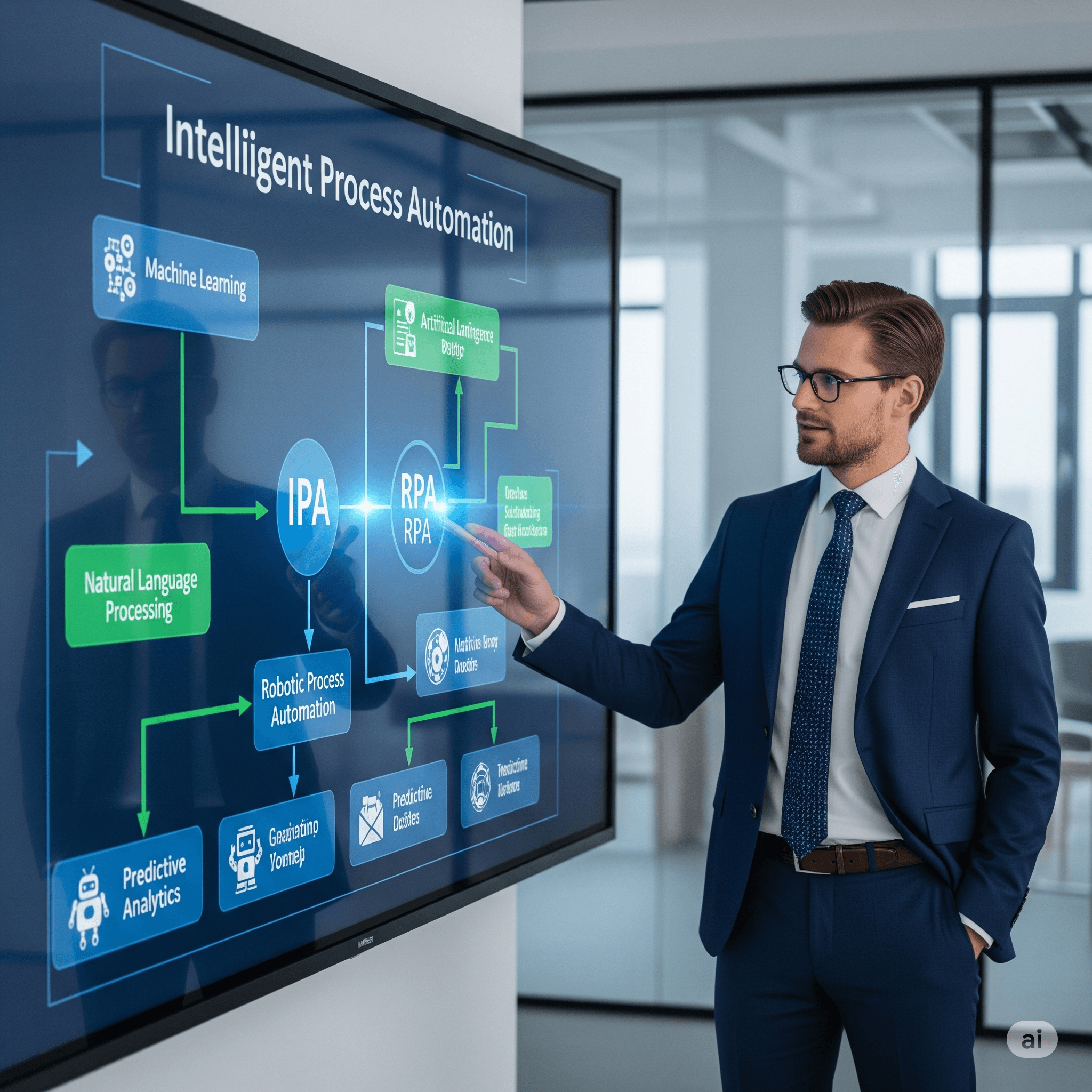

Cognitive supply chains represent a paradigm shift from linear, reactive models to interconnected, intelligent ecosystems that integrate artificial intelligence, machine learning, and advanced analytics into every aspect of supply chain operations. The architecture is built on five core elements: data-driven insights from massive amounts of information collected through sensors, IoT devices, and market trends; automation of routine tasks such as inventory management, procurement, and logistics; predictive analytics leveraging AI and ML models to forecast demand, identify potential disruptions, and optimize resources; real-time visibility providing complete end-to-end transparency across the entire supply chain network; and enhanced decision-making offering actionable insights that enable managers to make informed decisions quickly.

Transformation Impact

Adaptive robotics act on Internet of Things device information and structured and unstructured data to learn and make autonomous decisions, while natural language processing tools understand human speech and react accordingly, creating truly intelligent supply chain operations.

- Adaptive Learning Systems: Continuously evolving algorithms that learn from operational data, market patterns, and performance outcomes to optimize supply chain decisions

- Autonomous Decision-Making: AI-powered systems that make independent operational decisions based on real-time data analysis and predictive modeling

- Integrated Data Processing: Seamless integration of structured and unstructured data from multiple sources including sensors, documents, and external market intelligence

- Real-Time Optimization: Dynamic adjustment of operations based on changing conditions, demand patterns, and supply availability

- Predictive Intelligence: Advanced forecasting capabilities that anticipate disruptions, demand changes, and optimization opportunities

Demand Forecasting and Inventory Optimization

Cognitive technologies revolutionize demand forecasting by analyzing vast datasets including historical sales data, market trends, weather patterns, social media sentiment, and economic indicators to create highly accurate predictions that enable optimal inventory levels and reduce stockouts. Machine learning algorithms continuously refine forecasting models based on actual outcomes, seasonal variations, and external factors, achieving unprecedented accuracy in demand prediction while automatically adjusting inventory policies and procurement schedules. Leading retailers implementing cognitive demand forecasting have achieved significant improvements in inventory turnover, reduced carrying costs, and enhanced customer satisfaction through better product availability and optimized stock levels.

| Forecasting Application | Cognitive Technology Used | Business Impact | Performance Improvement |

|---|---|---|---|

| Demand Prediction | Machine learning algorithms analyzing multiple data sources | Reduced stockouts and overstock situations | Up to 50% improvement in forecast accuracy |

| Seasonal Planning | AI models incorporating weather, events, and historical patterns | Optimized inventory for seasonal variations | 35% reduction in excess inventory |

| New Product Introduction | Predictive analytics using market intelligence and trends | Better launch planning and inventory allocation | 60% improvement in new product success rates |

| Supply Risk Assessment | Real-time monitoring and predictive risk modeling | Proactive mitigation of supply disruptions | 40% reduction in supply-related stockouts |

Intelligent Logistics and Route Optimization

Cognitive logistics systems leverage artificial intelligence to optimize route planning, reduce fuel consumption, and enhance delivery performance through real-time analysis of traffic conditions, weather patterns, vehicle capacity, and customer preferences. Companies like DHL have implemented cognitive technologies to optimize route planning, reduce fuel costs, and enhance delivery times by predicting traffic conditions and weather disruptions, resulting in significant operational improvements and cost savings. Advanced logistics optimization systems can dynamically reroute vehicles based on real-time conditions, optimize loading sequences for maximum efficiency, and coordinate multiple delivery networks to minimize total transportation costs while improving service levels.

Logistics Performance

Cognitive logistics optimization enables companies to reduce transportation costs by up to 20% while improving on-time delivery performance and reducing carbon emissions through intelligent route planning and vehicle utilization.

Predictive Maintenance and Asset Management

Cognitive supply chain systems enable predictive maintenance by continuously monitoring equipment performance through IoT sensors and using machine learning algorithms to predict failures before they occur, minimizing downtime and optimizing maintenance schedules. Companies like Siemens have implemented cognitive supply chains in manufacturing processes, using sensors and IoT devices to predict machine failures before they happen, reducing downtime and optimizing resource allocation while improving overall equipment effectiveness. The integration of predictive maintenance with supply chain operations enables coordinated planning of spare parts inventory, maintenance scheduling, and production planning to minimize disruptions and optimize operational efficiency.

Supplier Risk Management and Collaboration

Cognitive technologies enable proactive supplier risk management by analyzing supplier performance data, financial health indicators, geopolitical factors, and external risk signals to identify potential disruptions before they impact supply chain operations. Advanced risk assessment systems monitor suppliers continuously, evaluate alternative sourcing options, and automatically trigger contingency plans when risk thresholds are exceeded, ensuring supply chain resilience and continuity. Intelligent supplier collaboration platforms use cognitive technologies to optimize supplier relationships, automate procurement processes, and enable real-time collaboration on demand planning, quality management, and performance improvement initiatives.

- Risk Monitoring: Continuous assessment of supplier financial health, operational capacity, and external risk factors

- Alternative Sourcing: Automated identification and evaluation of backup suppliers based on capability, cost, and risk profiles

- Performance Analytics: Real-time tracking of supplier performance metrics including quality, delivery, and compliance

- Collaborative Planning: Integrated demand planning and capacity management with key suppliers

- Automated Procurement: Intelligent procurement systems that optimize sourcing decisions based on multiple criteria

Real-Time Visibility and Control Tower Operations

Cognitive supply chain control towers provide real-time visibility into end-to-end operations through integrated dashboards that combine data from multiple systems, sensors, and external sources to enable proactive management and rapid response to disruptions. These intelligent control centers use machine learning algorithms to identify patterns, anomalies, and optimization opportunities while providing predictive alerts and automated recommendations for operational improvements. Advanced control tower systems can automatically coordinate responses to disruptions, reallocate resources based on changing priorities, and maintain optimal performance across complex, multi-tier supply networks.

Sustainability and Carbon Footprint Optimization

Cognitive technologies enable supply chain sustainability by optimizing resource usage, reducing waste, and minimizing carbon emissions through intelligent planning and execution of logistics operations. AI-powered systems analyze the environmental impact of different supply chain decisions, recommend sustainable alternatives, and track progress toward sustainability goals while maintaining operational efficiency and cost-effectiveness. Organizations implementing cognitive supply chain technologies report significant improvements in sustainability metrics including reduced energy consumption, lower carbon emissions, and more efficient use of packaging and transportation resources.

Sustainability Impact

Cognitive supply chains help organizations achieve sustainability goals by optimizing resource usage, reducing waste by up to 30%, and minimizing carbon emissions through intelligent route planning and operational efficiency improvements.

Customer Experience and Personalization

Cognitive supply chains enhance customer experience by enabling personalized service delivery, accurate delivery predictions, and proactive communication about order status and potential delays. Advanced customer analytics systems analyze purchasing patterns, preferences, and behavioral data to optimize inventory placement, customize product offerings, and provide personalized recommendations that improve customer satisfaction and loyalty. Real-time order tracking and intelligent customer service systems use natural language processing to provide accurate, context-aware responses to customer inquiries while automatically resolving common issues and routing complex problems to appropriate specialists.

Quality Management and Compliance Automation

Cognitive technologies transform quality management by automating inspection processes, predicting quality issues, and ensuring compliance with regulatory requirements through intelligent monitoring and analysis of quality data. Machine learning algorithms analyze production data, supplier quality metrics, and historical quality trends to identify potential quality issues before they result in defects or compliance violations. Automated compliance systems monitor regulatory changes, assess compliance risks, and implement necessary controls to ensure adherence to quality standards and regulatory requirements across global supply chain operations.

| Quality Application | Cognitive Technology | Automation Benefits | Compliance Impact |

|---|---|---|---|

| Inspection Automation | Computer vision and AI analysis | Faster, more accurate defect detection | Consistent quality standard enforcement |

| Supplier Quality | Predictive analytics and performance monitoring | Proactive quality issue prevention | Improved supplier compliance rates |

| Regulatory Monitoring | Natural language processing and compliance tracking | Automated regulatory change management | Reduced compliance violations and penalties |

| Traceability Management | Blockchain and IoT integration | End-to-end product traceability | Enhanced audit capabilities and transparency |

Integration with Emerging Technologies

The future of cognitive supply chains involves deeper integration with emerging technologies including blockchain for transparency and traceability, Internet of Things for real-time data collection, edge computing for local processing and faster response times, and advanced robotics for autonomous operations. Blockchain integration with cognitive technologies offers greater transparency, security, and traceability in supply chains while enabling automated smart contracts that execute based on predefined conditions and performance metrics. Edge computing capabilities enable real-time processing of supply chain data at the point of origin, reducing latency and enabling faster decision-making for time-sensitive operations.

Implementation Challenges and Solutions

Implementing cognitive supply chain technologies faces several challenges including data quality and availability issues, high implementation costs, complexity in system integration, cybersecurity risks from increased connectivity, and organizational resistance to change. Successful implementation requires addressing data integration complexity by establishing robust data governance frameworks, ensuring data quality through comprehensive cleansing and standardization processes, and implementing proper cybersecurity measures to protect sensitive supply chain information. Organizations should adopt phased implementation approaches starting with high-impact use cases, invest in employee training and change management programs, and establish clear governance frameworks to manage the complexity of cognitive supply chain systems.

Implementation Considerations

Organizations must carefully plan cognitive supply chain implementation by addressing data quality, system integration complexity, cybersecurity requirements, and change management to realize full benefits while minimizing risks.

ROI and Business Value Measurement

Measuring the return on investment and business value of cognitive supply chain implementations requires comprehensive metrics that capture both quantitative improvements in operational performance and qualitative enhancements in decision-making capabilities and customer satisfaction. Key performance indicators include cost reduction percentages, efficiency improvements, accuracy gains in forecasting and planning, customer satisfaction scores, and sustainability metrics such as carbon footprint reduction and waste elimination. Organizations should establish baseline measurements before implementation and continuously monitor performance improvements to optimize cognitive supply chain systems and demonstrate business value to stakeholders.

Future Trends and Evolution

The future of cognitive supply chains will be characterized by increased autonomy, enhanced sustainability focus, and deeper integration with emerging technologies that create fully autonomous supply chain ecosystems capable of self-optimization and adaptation. Future applications include autonomous supply chains where AI-driven systems handle everything from demand planning to last-mile delivery, blockchain integration for enhanced transparency and security, sustainability optimization through AI-powered resource management, and customized supply chains that enable on-demand production and highly personalized products and services. Advanced cognitive technologies will enable supply chains to become more resilient, adaptive, and efficient while supporting business growth and competitive advantage in dynamic global markets.

- Fully Autonomous Operations: Complete automation of supply chain processes from planning to execution with minimal human intervention

- Quantum Computing Integration: Advanced computational capabilities for complex optimization and predictive modeling

- Augmented Reality Applications: Enhanced warehouse operations, maintenance procedures, and quality control processes

- Digital Twin Technology: Virtual representations of supply chain operations for simulation, optimization, and scenario planning

- Circular Economy Integration: Cognitive systems optimizing product lifecycle management and sustainable resource utilization

Small Business Applications and Accessibility

Cognitive supply chain technologies are becoming increasingly accessible to small businesses through cloud-based platforms, affordable AI tools, and simplified implementation approaches that don't require massive capital investments. Small retailers and traders can benefit from AI-powered inventory management systems, predictive analytics for demand forecasting, automated reordering processes, and logistics optimization tools that were previously available only to large enterprises. Implementation strategies for small businesses include adopting cloud-based point-of-sale systems for data collection, using AI-driven inventory management solutions, implementing automated reordering for popular products, and leveraging predictive analytics for seasonal trend analysis.

Industry-Specific Applications and Case Studies

Different industries are implementing cognitive supply chain technologies in unique ways tailored to their specific operational requirements and challenges. In retail, companies like Amazon use cognitive technologies to optimize inventory levels, personalize customer experiences, and automate warehouse operations using robots and AI for rapid delivery capabilities. Manufacturing companies like Siemens leverage cognitive supply chains to predict machine failures, ensure just-in-time inventory management, and optimize production schedules, while healthcare organizations use these technologies for pharmaceutical supply chain optimization, demand forecasting, and temperature-sensitive logistics for vaccines and medical supplies.

| Industry Sector | Primary Applications | Key Benefits Achieved | Implementation Examples |

|---|---|---|---|

| Retail and E-commerce | Inventory optimization, demand forecasting, warehouse automation | Reduced stockouts, improved customer satisfaction, faster delivery | Amazon's AI-driven fulfillment centers, personalized recommendations |

| Manufacturing | Predictive maintenance, production optimization, quality control | Reduced downtime, improved efficiency, better quality outcomes | Siemens' predictive maintenance systems, smart factory integration |

| Healthcare and Pharmaceuticals | Cold chain management, regulatory compliance, demand planning | Improved product safety, regulatory adherence, optimized distribution | Vaccine distribution optimization, pharmaceutical traceability |

| Automotive | Just-in-time delivery, supplier coordination, quality assurance | Lean inventory, improved supplier relationships, quality consistency | Toyota's lean manufacturing, Tesla's direct-to-consumer model |

Strategic Implementation Roadmap

Developing a successful cognitive supply chain implementation requires a strategic roadmap that begins with current state assessment, identifies high-impact use cases, and establishes a phased implementation approach with clear milestones and success metrics. Organizations should start by digitizing existing processes, establishing data integration capabilities, and implementing basic analytics before progressing to advanced cognitive technologies. The roadmap should include data collection and digitization using cloud-based systems, AI-powered inventory management implementation, automation of reordering processes, predictive analytics for trend analysis, and integration with logistics and visibility platforms.

Implementation Success

Successful cognitive supply chain implementation requires a structured approach starting with data foundation, progressing through basic automation, and evolving to advanced cognitive capabilities while maintaining focus on business value and user adoption.

Conclusion

Cognitive technologies are revolutionizing supply chain operations by enabling unprecedented levels of intelligence, automation, and optimization that transform how organizations manage complex global networks and respond to dynamic market conditions. The integration of artificial intelligence, machine learning, and advanced analytics into supply chain operations creates self-learning, adaptive systems that continuously improve performance while reducing costs, enhancing customer satisfaction, and supporting sustainability goals. Organizations implementing cognitive supply chain technologies are achieving significant competitive advantages through improved forecast accuracy, reduced operational costs, enhanced resilience, and better customer service while positioning themselves for future growth in an increasingly complex and dynamic business environment. As cognitive technologies continue to evolve and become more accessible, the transformation of supply chain operations from reactive, linear processes to proactive, intelligent ecosystems will accelerate, making cognitive supply chain capabilities essential for business success in the digital economy. The future belongs to organizations that can effectively leverage cognitive technologies to create adaptive, resilient, and sustainable supply chains that respond dynamically to changing customer needs, market conditions, and global challenges while maintaining operational excellence and competitive differentiation.

Reading Progress

0% completed

Article Insights

Share Article

Quick Actions

Stay Updated

Join 12k+ readers worldwide

Get the latest insights, tutorials, and industry news delivered straight to your inbox. No spam, just quality content.

Unsubscribe at any time. No spam, ever. 🚀